FS Reloading Blogs

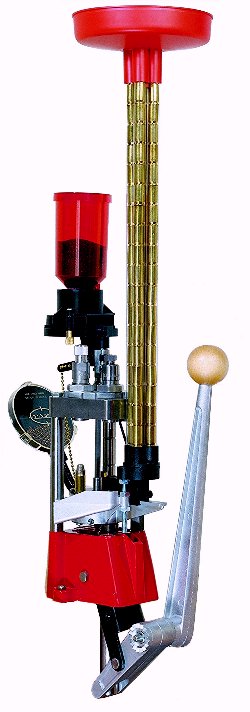

Lee Pro 1000

LEE PRO 1000

Change Calibers in 3 minutes

Add a bullet and pull the lever; all other operations are automatic. One loaded cartridge with each pull of the lever.

Every operation is automatic. Primers, like the powder, are fed only if a case is present. No wasted primers or spilled powder. Alternate loading sequence lets you load only one case at a time. Makes learning easy for the first time user and great for fine adjustments or experimenting.

You can start reloading good ammunition minutes after the press is bolted down.

Notes:

- Lee Precision Pro 1000 is pictured with the optional Case Collator which is sold separately below.

- 32 S&W also loads 32 H&R Magnum.

- 38 Special also loads 357 Magnum.

- 44 Special also loads 44 Magnum.

- .223 Remington Includes Rifle Charging Die. Not available in carbide.

- When Switching from .223 rifle to pistol PLEASE ADD STANDARD Z BAR TR2452A for 9mm or BENT Z BAR TR2452B for .45 ACP

The optional Case Collator is not included with Pro 1000 Press. It must be ordered separately. The optional Case Collator is not included with Pro 1000 Press. It must be ordered separately. |

Load Master & Pro 1000 difference

The Main difference between the Load Master and the Pro-1000 is that the Load Master is designed to handle rifle and pistol, and the Pro 1000 is designed primarily for pistol cartridges, but will reload rifle cartridges up to 2 5/16" in overall length. The Load Master is a five station press, the Pro 1000 is three. Both include automatic indexing, automatic primer feed and case feed, and both can be fitted with an automatic bullet feed. Both come set up with everything you need to start loading the caliber chosen. People who wish to load rifle or use the Lee Precision Carbide Factory Crimp dies for handgun loading normally opt for the Load Master. Caliber changer overs for both presses can be done in less than five minutes. The Load Master is a little more costly to purchase and to change calibers. Both presses are designed for experienced reloaders. That is not to say that a first time reloader shouldnt order one, but one should have good mechanical aptitude to start with a progressive.

Shell Plates

Shell Plates

If you order Shell Plates to convert to another caliber with a different primer size, be sure to order the Pro 1000 Primer Attachment.

Shell Plate Carrier

To change calibers, the entire Shell Plate Carrier can be replaced. Each unit comes complete with Shell Plate, Auto Prime, Case Ejector, Auto-Index and spare parts.

To change calibers, the entire Shell Plate Carrier can be replaced. Each unit comes complete with Shell Plate, Auto Prime, Case Ejector, Auto-Index and spare parts.

![]()

Case Feeder

LARGE CASE FEEDER

![]() 38 SPECIAL

38 SPECIAL ![]() 357 Magnum

357 Magnum ![]() 41 Magnum

41 Magnum ![]() .44 Special

.44 Special ![]() 44 Magnum

44 Magnum ![]() 45 ACP

45 ACP ![]() .45 Colt

.45 Colt ![]() 10mm Auto

10mm Auto ![]() 7.62 x 39 RUSSIAN

7.62 x 39 RUSSIAN

40 S&W uses the Large Case Feeder with a small slider.

SMALL CASE FEEDER

![]() 9mm Luger

9mm Luger ![]() 380 Auto

380 Auto ![]() 32 Auto

32 Auto ![]() 32 S&W Long

32 S&W Long ![]() 32 H&R Magnum

32 H&R Magnum ![]() 38 Auto

38 Auto ![]() 38 SUPER

38 SUPER

RIFLE CASE FEEDER

![]() .222 Remington

.222 Remington ![]() .223

.223 ![]() 30 M1 Carbine

30 M1 Carbine

Extra Case Feeder Tubes(7 PACK)

Case Collator

Case Collator

Fills all four tubes in just ten seconds. For the Pro 1000 or Load Master

THIS IS A MUST HAVE ITEM WHEN YOU ORDER THE PRO 1000 OR LOAD MASTER......

Adjustable Charge Bar

.jpg) Bullet Feed Kit

Bullet Feed Kit

The bullet feeder designed to directly fit the Pro 1000 and Load Master. Automatically feeds bullets into the mouth of the seating die. Align bullets more accurately than possible by hand. Increases the cyclic rate 50 to 100%. The Bullet Feed Kit is complete for one bullet diameter and range of length. To convert to another caliber or bullet length select appropriate Feed die & finger.

Feed Kits Complete

Feed Die and Fingers

Multi-Tube Adapter for Bullet Feed Kit

Multi-Tube Adapter for Bullet Feed Kit

Four tube magazine keeps Lee Precision Bullet Feeder fed with a continuous supply of bullets. Quickly and easily installed. Includes large and small adapters, four large and small feed tubes and cylinder, plate assembly.

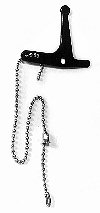

Pro Auto-Disk Update Kit

Pro Auto-Disk Update Kit

Update any Lee Precision Auto-Disk Powder Measure with all the PRO features, except for the teflon coating. Includes oversize hopper and valve assembly with elastomer wiper, swivel adapter assembly for fast and easy transfer between die sets, pullback lever, chain and attachments, solid brass knurled thumb nuts. With FREE adjustable Charge Bar.

Auto Disk Pull Back Lever

Auto Disk Pull Back Lever

Pullback lever for progressive reloading. Eliminates the possibility of powder binding while reducing the chance of missed or double charges caused by operator error.

Swivel Adapter

Swivel Adapter

For fast and easy transfer between die sets. Screws into your die without rotating the measure. Allows precise positioning with firm clamping.

Meet Some Satisfied Customers!

David E. from Longview, WA:

For the last year and a half I have been using your fine Progressive 1000 press. In this time I have loaded approximately 8000 round of .45 ACP with excellent results! The ammo is consistent in quality and accuracy I have no complaints whatsoever. I have used Dillon, RCBS, C&H, Hornady and Star Auto presses. All of these are fine products and have served me well in the last 17 years, but all of these presses had or have small quirks that I had to overcome in order to make them work for me. I wont go into specifics here but I will say that they had to do with case and primer feeding. Your case feeding system for a small scale press is second to none! It is simple and once setup, is entirely bulletproof in operation (bad pun, sorry). The most touchy part of ANY reloader is the handling and delivery of primers. Frankly, if I could afford it, I would buy all of my cases new and factory primed. But since the main reason I reload at all is to save money, this isnt an option. Until I got my Pro 1000, case priming was a separate operation performed on the washing machine in the garage. Like I said, 8000 rounds in the last 18 months and without mishap. I use only CCI 350s. Not because you folks said so but because they work the best with my .45ACP loads. I belong to and shoot with the local USPSA/IPSC club. A lot of the guys use this press and find it to be the best for the money.....Again, thanks for building this fine press.

David S. from Jasper, GA:

I recently purchased a Lee Precision Pro 1000 loader in 9mm Luger from Midway in Missouri. I wanted to let you know how pleased I am with this excellent piece of equipment. I had seen the 1000 advertised in several flyers, etc. However, I was convinced to get one after reading an article about it in "SWAT" magazine (a special issue devoted to high capacity 9mm pistols). I have a progressive shot shell reloader (a MEC Grabber), but my reloading experience in metallic cartridges was limited to a single stage press. Using the 1000 has been a revelation. The rounds are consistent, and the only malfunctions Ive had in reloading have been the result of "breaking in" the operator-Me! Your directions and instructions are excellent. Overall, I am delighted with the loader, as I am with all my Lee Precision products (dies, bullet sizers, lead furnace, auto-prime, etc.) Keep up the good work!!!

John R. from Sacramento, CA:

The enclosed decapper pin was installed in a Lee Precision Carbide Pistol Die Set I purchased In January of this year. It broke while reloading ammunition. I am very pleased with the performance, as I had reloaded approximately 9,000 rounds with it; however, I would like you to replace it under the terms of your warranty. As a passing note, Ive been using a Lee Precision Pro 1000 for almost 2 years and it is SUPER! I bought it as a novice reloader and have found it to be exceptionally forgiving when I started and exceptionally accommodating now that I have some proficiency. Thank you.

William J. from Rockaway, NJ:

.....I have used your molds as well as most of your other equipment for many years with great satisfaction and have recommended and sold your equipment to my customers and friends for as long. I have loaded almost 100,000 rounds of .380 Auto ammo on one of your Progressive 1000 presses. I have taken it apart three times to clean and lubricate it and modified one part to increase reliability (the finished round ejector sometimes let a round fall onto the shell plate instead of pushing it into the discharge shoot) otherwise I have had no breakages or serious problems. Keep up the good work!

David K. from Powder Springs, GA:

Today I called your complaint department to complain about my Lee Precision Pro 1000 press, .38 & .357 caliber. Ive had this press about 6 or 7 years and have loaded many thousands of rounds with it and yesterday I had to break the thing down and clean it. It finally started giving me some trouble with the primer dispensing. I am something of a do it yourselfer, and I like to tinker with the equipment that I use in my hobbies. I made some modifications on my Delta table saw, and improved its performance a good deal. I bedded the action on my custom Mauser, and cut my group size in half. My complaint is that you built this darned thing so well that I cant find anything to tinker with on it. I have had no trouble with it and have had to clean it only this one time and I hate it. I hate it so much I just bought another Lee Precision Pro 1000 in 9mm. I guess Ill wind up hating it, too. When I got the Pro 1000, I set it up and the first day loaded 1500 rounds of 9mm flawlessly. You build your stuff too well. Thank you for giving the public something that really works.

Gary K. from Live Oak, TX:

I just wanted to drop you a line to express how very pleased I have been with Lee Precision reloading equipment. I purchased a Lee Precision Pro 1000, through Midway, Inc., during October 1990. Since then, I have purchased taper crimp dies, and other accessories, all Lee Precision where possible. I shoot about 15 to 20 boxes of .380, 9mm, .45, .38 spl and/or .357 per month. There is no way I could afford that level of activity without the benefit of reloading my own ammunition. Translated into number of rounds....I have reloaded over 32,000 rounds of ammunition with my Pro 1000! As a separate step, I also decap and size all previously fired cases with my Pro 1000. That means, all total, that my Pro 1000 has been through over 128,000 complete "up and down" cycles! It has never failed me, and to this day, performs flawlessly. I have been so impressed with my Pro 1000 that about two years ago I had an opportunity to buy a "nearly new" used Pro 1000.I did so on the chance that I might need some spare parts some day. I have yet to crack the box containing the second Pro 1000!

Read More by Staff

- 10 Day Gun Cleaning Super Sale (Expired 05 Aug 2014)

- 10 Day Gun Cleaning Super Sale (Expired 31 Jul 2014)

- 2013 SHOT Show

- A Year of Great Changes

- About Our Site

- Administration Help

- Ammo Storage

- Automatic Powder Measures

- Black Friday All Week (Expired 01 Dec 2014)

- Black Friday All Week (Expired 03 Dec 2014)

- Black Friday All Week (Expired 28 Nov 2014)

- Black Friday Comes Early (Expired 23 Nov 2015)

- Black Friday Lee Specials (Expired 02 Dec 2015)

- Black Powder

- Bullet Casting and Case Lubricant

- Bullet Casting Blow-out (Expired 12 Nov 2014)

- Bullet Casting Special (Expired 23 Jan 2015)

- Bullet Molds

- Bullet Pictures

- Bullet Puller and Reloading Stand

- Caldwell Overstock Specials from FS Reloading (Expired 02 Sep 2015)

- Caldwell Range Gear Special (Expired 22 Oct 2014)

- Caldwell Range Gear Specials from FS Reloading (Expired 18 Aug 2015)

- Caldwell Shooting Gear Specials from FS Reloading (Expired 29 Apr 2016)

- Caldwell Shooting Rests and Bags (Expired 21 Nov 2014)

- Caldwell Shooting Supplies Warranty

- Caldwell Special Offers from FS Reloading (Expired 27 Apr 2015)

- Caldwell Target Special Offers from FS Reloading (Expired 08 May 2015)

- Caliber Nomenclature and Formatting Rules

- Calibers

- Calipers and Scales

- Case Cleaning Tools and Supplies (Expired 09 Oct 2014)

- Case Cleaning Tools and Supplies (Expired 13 Aug 2014)

- Case Conditioning Deals (Expired 19 Jan 2015)

- Case Conditioning Special Offers (Expired 22 Apr 2015)

- Case Conditioning Specials from FS Reloading (Expired 28 Oct 2015)

- Case Conditioning Tools

- Case Conditioning Tools & Supplies (Expired 31 Oct 2014)

- Case Lubes

- Categories

- Classic Cast

- Clean Up With Savings On Case Cleaning Tools and Supplies (Expired 27 Aug 2014)

- Cyber Monday Case Conditioning Specials (Expired 07 Dec 2015)

- Cyber Monday Continues All Week (Expired 08 Dec 2015)

- Cyber Monday Shooting Gear (Expired 08 Dec 2014)

- Dealers

- Deluxe Pistol Reloading Kit

- Die Tables

- Discontinued Products

- Download Orders

- Factory Crimp

- Field Shield and Mag Shields

- FrankFord Arsenal Quick-n-Ez Case Tumblers

- Frankford Arsenal Reloading Tools and Supplies (Expired 15 Dec 2014)

- FrankFord Arsenal Reloading Tools Warranty

- Frankford Arsenal Special Offers (Expired 13 Feb 2015)

- Frankford Arsenal Specials from FS Reloading (Expired 06 Oct 2016)

- Frankford Arsenal Specials from FS Reloading (Expired 15 Aug 2015)

- Frankford Arsenal Specials from FS Reloading (Expired 18 Jan 2016)

- Frankford Arsenal Specials from FS Reloading (Expired 21 Apr 2017)

- Frankford Arsenal Specials from FS Reloading (Expired 23 May 2016)

- Frankford Arsenal Specials from FS Reloading (Expired 29 Nov 2016)

- Frankford Arsenal Tools & Supplies (Expired 17 Nov 2014)

- Frankford Arsenal Tools from FS Reloading (Expired 14 Apr 2016)

- FrankFord Arsenal UltraSonic Cleaners

- FS Reloading Ammo Box Specials (Expired 22 Dec 2014)

- FS Reloading Ammo Box Specials (Expired 29 Apr 2015)

- FS Reloading Bullet Casting Specials (Expired 06 May 2015)

- FS Reloading Newsletter Schedule

- FS Reloading Rifle Ammo Box Specials (Expired 11 Aug 2015)

- FS Reloading Standard Image Sizes

- Grand Re-Opening Bullet Casting Special (Expired 08 Jul 2016)

- Grand Re-Opening Case Conditiong Special (Expired 02 Jul 2016)

- Grand Re-Opening Pistol Reloading Die Special (Expired 03 Jul 2016)

- Grand Re-Opening Powder Handling Special (Expired 05 Jul 2016)

- Grand Re-Opening Rifle Reloading Die Special (Expired 04 Jul 2016)

- Gun Cleaning Sale from FS Reloading (Expired 21 Sep 2016)

- Gun Cleaning Specials from FS Reloading (Expired 09 May 2016)

- Gun Cleaning Super Sale from FS Reloading (Expired 16 Sep 2015)

- Gun Cleaning Tools (Expired 18 Feb 2015)

- Gun Cleaning Tools from FS Reloading (Expired 24 Mar 2016)

- Gunsmithing Special Offers (Expired 31 Jan 2015)

- Gunsmithing Specials from FS Reloading (Expired 22 Jul 2015)

- Gunsmithing Super Sale (Expired 21 Aug 2014)

- Gunsmitthing Specials from FS Reloading (Expired 23 Dec 2016)

- Hidden Comfort Recoil Shield For Women

- Home

- How-To Videos

- Import Lee Precision

- Import/Export Products

- Instruction Sheets

- Lee 50th Aniversary Breech Lock Kit

- Lee Bench Plate

- Lee Breech Lock Classic Cast Press

- Lee Bullet Casting Specials from FS Reloading (Expired 15 Oct 2015)

- Lee Collet Dies

- Lee Collet Neck Sizing Die

- Lee Die Accessories

- Lee Dies

- Lee Large Series Dies

- Lee Loader

- Lee PaceSetter Dies

- Lee Pistol Die Special (Expired 01 Oct 2014)

- Lee Precision New for 2013

- Lee Precision New Items 2015

- Lee Precision Rifle Die Blow Out Special (Expired 13 Aug 2014)

- Lee Precision Specials from FS Reloading (Expired 26 May 2015)

- Lee Precision Specials from FS Reloading (Expired 26 May 2017)

- Lee Precision Warranty

- Lee Quick Trim

- Lee Reloading Die Specials from FS Reloading (Expired 03 Oct 2015)

- Lee Reloading Dies & Accessories Sale (Expired 14 Sep 2016)

- Lee Reloading Stand

- Lee Rifle Reloading Dies (Expired 25 Feb 2015)

- Lee Safety Powder Scale/Digital Scales

- Load All

- Load Master

- Lubes and Sizing

- Making Good Product Photos

- Marketing

- Melters

- Mid-Summer Lee Precision Sale (Expired 17 Aug 2016)

- Mid-Summer Reloading Equipment Sale (Expired 30 Jul 2016)

- Missing Product Pictures

- Modern Reloading

- More Black Friday Lee Specials (Expired 04 Dec 2015)

- More Black Friday Specials (Expired 26 Nov 2015)

- More New Year's Shooting Gear Deals (Expired 12 Jan 2015)

- New Year's Shooting Gear Deals (Expired 09 Jan 2015)

- New Years Specials from FS Reloading (Expired 07 Jan 2016)

- Orders

- Our Web Design Team

- PAST Recoil Protection Warranty

- Perfect Powder Measure

- Pistol Dies

- Powder and Primer Handling

- Powder Handling Special Offers (Expired 27 Mar 2015)

- Press Kits

- Prices Reduced On Caldwell Shooting Supplies (Expired 26 Dec 2014)

- Priming Tools

- Product Help Items

- Products

- Range Gear Special (Expired 20 Mar 2015)

- Range Gear Special Offers from FS Reloading (Expired 21 May 2015)

- Reloading Presses

- Reloading Specials from FS Reloading (Expired 12 Jan 2017)

- Reloading Tool Specials from FS Reloading (Expired 11 Feb 2017)

- Reloading Trays

- RGB Dies

- Rifle Ammo Box Specials from FS Reloading (Expired 17 Jul 2015)

- Rifle Reloading Dies (Expired 29 Dec 2014)

- SALES AND USE TAX POLICY

- Save on Caldwell Shooting Gear (Expired 04 Feb 2015)

- Save on Case Conditioning Tools and Supplies (Expired 19 Dec 2014)

- SAVE on Do-it-Yourself Tools (Expired 06 Nov 2014)

- Save on New for 2014 Products (Expired 04 Sep 2014)

- Save on New for 2014 Products (Expired 10 Sep 2014)

- Save on Popular Cleaning Tools & Supplies (Expired 11 Dec 2014)

- Save on Popular Shooting Gear (Expired 26 Jan 2015)

- Save on Popular Tipton Cleaning Tools (Expired 24 Dec 2014)

- Save on Reloading Supplies (Expired 21 Jan 2015)

- Save on Tipton Carbon Fiber Cleaning Rods (Expired 02 Jan 2015)

- Save on Tipton Carbon Fiber Cleaning Rods (Expired 08 Apr 2015)

- Save on Tipton Carbon Fiber Cleaning Rods (Expired 15 Oct 2014)

- Save on Wheeler Engineering Gunsmithing Tools (Expired 05 Jan 2015)

- Save Twice with Do-It-Yourself Tools (Expired 17 Sep 2014)

- Shooting Gear Specials (Expired 05 Mar 2015)

- Shooting Gear Specials (Expired 26 Nov 2014)

- Shooting Gear Specials from FS Reloading (Expired 01 Feb 2017)

- Shooting Gear Specials from FS Reloading (Expired 03 Feb 2016)

- Shooting Gear Super Sale from FS Reloading (Expired 23 Sep 2015)

- Special Offers from FS Reloading (Expired 14 Jun 2017)

- Stocking Stuffer Deals from FS Reloading (Expired 18 Dec 2015)

- The Lead Sled Family

- Tipton Bore Brushes and Bore Mops

- Tipton Bore Brushes, Mops and Jags (Expired 19 Nov 2014)

- Tipton Bore Guides and Patch Trap

- Tipton Carbon Fiber Cleaning Rods

- Tipton Cleaning Tools Blowout (Expired 25 Sep 2014)

- Tipton Cleaning Tools Special Offers (Expired 21 Apr 2015)

- Tipton Gun Cleaning Specials from FS Reloading (Expired 25 Aug 2015)

- Tipton Gun Cleaning Supplies Warranty

- Tipton Gun Vises

- Tipton Jags

- Tipton Maintenance Supplies and Accessories

- Tipton Overstock Specials from FS Reloading (Expired 03 Sep 2015)

- Tipton Solvent and Solvent Supplies

- Top Brass

- Top Brass Warranty

- Ultimate Rifle Die Sets

- Update SEO & Help Icons

- US Balance Warranty

- US-ABSOLUTE Touch Screen 200g x 0.01g

- Vibra-Prime

- Wheeler Engineering Fine Gunsmithing Supplies Warranty

- Wheeler Engineering Overstock Specials from FS Reloading (Expired 05 Sep 2015)

- Writing Good Product Descriptions

- YouTube Videos